[:id]

BANDUNG, itb.ac.id – Susu merupakan salah satu jenis produk pangan yang paling populer sampai saat ini untuk berbagai kalangan usia mulai dari bayi, anak-anak, orang dewasa, hingga lansia. Susu juga menjadi produk yang digemari karena rasanya dan manfaat kesehatannya. Susu yang dikenal luas sebagai produk alamiah dari berbagai jenis tanaman dan binatang mamalia ternyata mengalami proses yang cukup panjang sebelum dapat dikonsumsi oleh kita.

Pada Sabtu (9/4/2022), Program Studi Teknik Pangan dan PT Langgeng Ciptalindo berkolaborasi dalam mengadakan kuliah tamu tentang “Liquid Milk Processing” yang dibawakan oleh Technical Project Manager dari PT Perfetti Van Melle Indonesia, Dedy Sandi Waskita, S.T., PMP., PRINCE 2.0. untuk mata kuliah PG4094 Perancangan Pabrik Pangan.

Secara umum, pemrosesan produk pangan pada skala industri dilakukan berdasarkan material dan fase produk yang terlibat. Jenis produksi ini terbagi ke dalam tiga jenis yaitu solid and liquid process, liquid and solid process, dan liquid and liquid process. Pemrosesan dan produksi susu termasuk ke dalam jenis liquid and liquid process karena material phase, in process, dan final product nya berupa liquid atau cairan. “Salah satu fokus utama dalam pengolahan susu adalah heat treatment yang salah satu tujuannya adalah untuk unsur higienitas,” ujar Dedy.

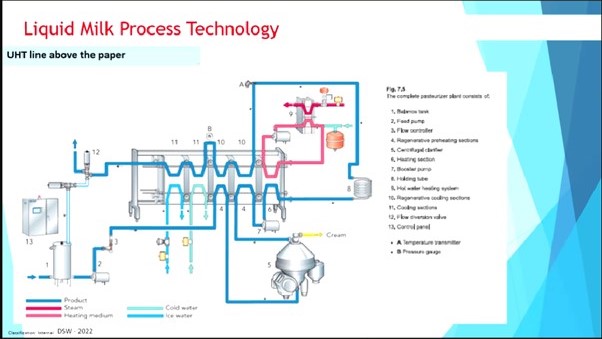

Peralatan yang terlibat dalam pemrosesan susu di industri pangan juga sangat beragam. Mulai dari process water heater, mixing tank, high shear mixer, chocco slurry tank, dan storage tank yang bekerja secara berurutan.

Pertama pada process water heater terjadi pemanasan air untuk menaikan temperatur. Kemudian mixing tank bekerja untuk mencampur zat yang dibutuhkan baik powder maupun liquid. High Shear Mixer berfungsi untuk menciptakan susu dengan komposisi yang sesuai kebutuhan dan keinginan. Lalu proses produksi berlanjut ke choco slurry tank yang berfungsi untuk memberi varian rasa pada susu, dan akhirnya hasil dari pemrosesan susu akan disimpan pada storage tank.

Dalam perancangan pemrosesan susu di pabrik, terdapat beberapa tahap yang harus dilalui. Prosesnya dimulai dari pemenuhan design requirement yang mengacu pada customer requirement dan standar vendor.

Lalu ada design phase yang melibatkan berbagai insinyur dari berbagai bidang ilmu keteknikan seperti process engineer dari Teknik Pangan dan Teknik Kimia, mechanical engineer dari Teknik Mesin, electrical engineer dari Teknik Elektro, dan juga automation engineer dari Teknik Fisika. Tahap selanjutnya adalah fase instalasi dan juga commissioning.

Pada tahap commissioning ini berbagai protokol kualifikasi instalasi harus dipenuhi sesuai standar. Mulai dari berbagai material dan item list, seal or elastomer certificate yang sudah memenuhi food grade, slope test report, welding map, 3D and PID drawing validation report, boroscope welding report, welding log report, welding test piece validation, hidrotest report, dan CIP validation test yang meliputi conductivity performance test, swab test performance, dan riboflavin performance test.

Reporter: Yoel Enrico Meiliano (Teknik Pangan, 2020)

[:en]

BANDUNG, itb.ac.id – Milk is one of the most popular types of food products to date for various ages ranging from infants, children, adults, to the elderly. Milk is also a popular product because of its taste and health benefits. Milk, which is widely known as a natural product from various types of plants and mammals, actually undergoes a long process before it can be consumed by us.

On Saturday (9/4/2022), the Food Engineering Study Program and PT Langgeng Ciptalindo collaborated in holding a guest lecture on “Liquid Milk Processing” which was presented by the Technical Project Manager from PT Perfetti Van Melle Indonesia, Dedy Sandi Waskita, S.T., PMP. , PRINCE 2.0. for the course PG4094 Food Plant Design.

In general, the processing of food products on an industrial scale is carried out based on the materials and product phases involved. This type of production is divided into three types, namely the solid to liquid process, the liquid to solid process, and the liquid to liquid process. Processing and production of milk is included in the type of liquid to liquid process because the material phase, in process, and the final product is in the form of liquid . “One of the main focuses in milk processing is heat treatment, one of which is for the element of hygiene,” said Dedy.

The equipment involved in milk processing in the food industry is also very diverse. Starting from the process water heater, mixing tank, high shear mixer, chocco slurry tank, and storage tank that work sequentially.

First, in the water heater process, water heating occurs to raise the temperature. Then the mixing tank works to mix the required substances, both in powder and liquid materials. High Shear Mixer serves to create milk with a composition that suits your needs and desires. Then the production process continues to the choco slurry tank which functions to give a variant of the taste to the milk, and finally the results from the milk processing will be stored in the storage tank.

In the design of milk processing in the factory, there are several stages that must be passed. The process starts from fulfilling design requirements that refer to customer requirements and vendor standards.

Then there is the design phase which involves various engineers from various fields of engineering such as process engineers from Food Engineering and Chemical Engineering, mechanical engineers from Mechanical Engineering, electrical engineers from Electrical Engineering, and also instrumentation engineers from Engineering Physics. The next stage is the installation and commissioning phase.

At this commissioning stage, various installation qualification protocols must meet the standards. Starting from various materials and items list, seal or elastomer certificate that fulfill food grade, slope test report, welding map, 3D and PID drawing validation report, boroscope welding report, welding log report, welding test piece validation, hydrotest report, and CIP validation test which includes conductivity performance test, swab test performance, and riboflavin performance test.

Reporter: Yoel Enrico Meiliano (Food Engineering, 2020)

[:]