[:id]

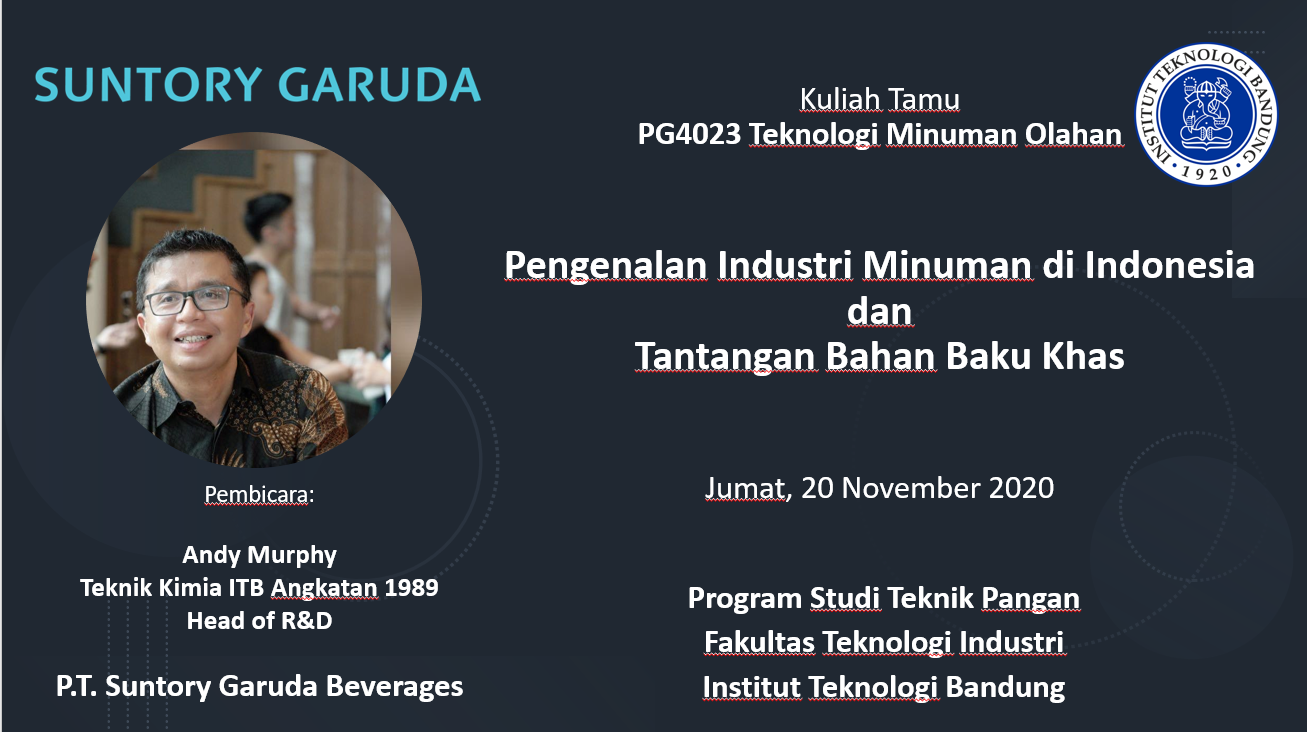

Program studi Teknik Pangan Institut Teknologi Bandung kembali mengadakan kuliah tamu untuk menambah wawasan dan memperlengkapi mahasiswa dengan penerapan ilmu yang telah dipelajari di kelas. Kuliah tamu kali ini diselenggarakan dalam kuliah PG4023 Teknologi Minuman Olahan pada hari Jumat, 20 November 2020 dengan mengusung tema “Pengenalan Industri Minuman di Indonesia dan Tantangan Bahan Baku Khas” yang dibawakan oleh Bapak Andy Murphy, kepala bagian Research and Development PT Suntory Garuda Beverages (SGB).

Industri ini masih terus berkembang dengan laju yang cukup tinggi bahkan di tengah keadaan pandemi. Jenis-jenis minuman dengan penjualan terbesar dimulai dari yang tertinggi adalah air minum dalam kemasan, minuman teh, minuman berperisa buah dan jus, minuman berkarbonasi, minuman kopi, dan minuman isotonik dan energi.

Setiap jenis minuman ini memiliki kompleksitas teknologi dan tantangan tersendiri terutama dalam hal keamanan pangan dan stabilitas kualitas selama masa simpan. Misalnya minuman teh kemasan memiliki pH netral sehingga lebih ideal untuk pertumbuhan mikroba berbahaya; minuman teh pun rawan teroksidasi selama penyimpanan yang dapat berakibat pada hilangnya rasa dan aroma teh.

Demikian pun terdapat tantangan dalam hal perancangan produk minuman agar dapat memenuhi pemintaan dan ekspektasi konsumen. “Dalam perancangan produk minuman yang akan dijual ke pasar, diperlukan pemikiran mengenai masalah apa yang dapat diselesaikan dengan adanya produk ini, ” tutur Pak Andy Murphy.

Untuk memenuhi perubahan permintaan konsumen dan pasar industri minuman yang semakin kompetitif, inovasi dalam pemrosesan minuman pun menjadi penting termasuk pemanfaatan keanekaragaman hayati Indonesia sebagai bahan baku minuman. Indonesia memiliki berbagai bahan baku khas seperti air kelapa sebagai bahan utama nata de coco, rumput laut untuk produksi karagenan, dan ekstrak dari tanaman porang sebagai substitusi konjac gum.

“Yang menjadi masalah adalah bangsa Indonesia umumnya lebih suka mengekspor bahan mentah lalu mengimpor bahan yang telah diproses di luar negeri dengan harga yang jauh lebih mahal, dibandingkan dengan mengolah sendiri di dalam negeri”, ucapnya.

Sebagai penutup, beliau menyampaikan berbagai tantangan dalam industri minuman olahan yang dapat dipecahkan oleh lulusan Teknik Pangan. Hal pertama adalah inovasi dalam perancangan produk untuk menurunkan kadar gula, garam, dan lemak tanpa mengorbankan kualitas rasa produk. Kedua, inovasi dalam kemasan plastik sangat diperlukan untuk menjaga lingkungan, misalnya dengan mencari alternatif bahan yang lebih mudah terurai, metode baru dalam hal daur ulang, ataupun rencana bisnis baru untuk menghasilkan industri yang lebih berkelanjutan.

Partisipan kuliah tamu sangat antusias dan menyampaikan banyak pertanyaan yang sebagian besar langsung dijawab oleh Pak Andy. Kuliah selama tiga jam ini ditutup dengan penyerahan sertifikat oleh Ketua Program Studi Teknik Pangan, Dr. Ronny Purwadi, dan juga acara foto bersama.

[:en]

[:en]

The Food Engineering Department at the Bandung Institute of Technology held another guest lecture to add insight and equip students with the application of the knowledge they had learned in class. This guest lecture was held in the PG4023 lecture on Processed Beverage Technology on Friday, November 20, 2020 with the theme “Introduction to the Beverage Industry in Indonesia and the Challenge of Typical Raw Materials” presented by Mr. Andy Murphy, head of the Research and Development section of PT Suntory Garuda Beverages SGB).

This industry is still growing at a fairly high rate even in the midst of a pandemic. The types of drinks with the biggest sales starting from the highest are bottled drinking water, tea drinks, fruit and juice flavored drinks, carbonated drinks, coffee drinks, and isotonic and energy drinks.

Each type of drink has its own technological complexity and challenges, especially in terms of food safety and quality stability during shelf life. For example, packaged tea drinks have a neutral pH so they are more ideal for the growth of harmful microbes; tea drinks are also prone to oxidation during storage which can result in loss of tea flavor and aroma.

Likewise, there are challenges in designing beverage products in order to meet consumer demands and expectations. “In designing beverage products that will be sold to the market, it is necessary to think about what problems can be solved with this product,” said Mr. Andy Murphy.

To meet changing consumer demands and the increasingly competitive beverage industry market, innovation in beverage processing is also important, including the use of Indonesia’s biodiversity as raw material for beverages. Indonesia has a variety of distinctive raw materials such as coconut water as the main ingredient for nata de coco, seaweed for carrageenan production, and extracts from the porang plant as a substitute for konjac gum.

“The problem is that the Indonesian nation generally prefers to export raw materials and then import materials that have been processed abroad at a much higher price, compared to processing it at home,” he said.

In closing, he conveyed various challenges in the processed beverage industry that can be solved by Food Engineering graduates. The first is innovation in product design to reduce levels of sugar, salt and fat without compromising the taste quality of the product. Second, innovation in plastic packaging is needed to protect the environment, for example by looking for alternatives to materials that are more biodegradable, new methods of recycling, or new business plans to produce a more sustainable industry.

Participants in the guest lecture were very enthusiastic and asked many questions, most of which Mr. Andy answered immediately. The three-hour lecture was closed with a certificate handover by the Head of the Food Engineering Study Program, Dr. Ronny Purwadi, and also a group photo event.

[:]

[:]

[:en]

[:en]

[:en]

[:en]