[:id]

BANDUNG, itb.ac.id–Kopi adalah salah satu jenis minuman paling populer dan digemari di Indonesia bahkan di dunia. Selain memiliki rasa yang disukai banyak orang, kopi juga dikenal memiliki manfaat bagi kesehatan. Indonesia merupakan salah satu negara yang menghasilkan varietas biji kopi yang beragam dan berkualitas tinggi. Berbagai jenis olahan kopi telah dikenal luas di Indonesia.

Pada acara kuliah tamu untuk mata kuliah PG2206 Pangan Terfermentasi, Jumat (1/4/2022), Prodi Teknik Pangan, Fakultas Teknologi Industri ITB, dijelaskan salah satu metode pengolahan kopi dengan fermentasi oleh Ir. Eddy Kemenady., M.M., M.P. dari Kemenady Coffee and Co-Working Space.

Di awal materi, Eddy menjelaskan terkait kandungan dalam biji kopi. Kandungannya terdiri dari dua bagian utama yaitu lendir kopi atau mucilage dan daging buah kopi atau pulp. Selain itu, bagian lain yang terdapat pada biji kopi adalah parchment, silverskin, dan bean.

Secara komposisi kimia, lendir buah pada kopi didominasi oleh air hingga 84,2%. Lendir buah pada biji kopi juga terdiri dari protein sebesar 8,9% dan gula 4,1%. Sementara, kadar air pada daging buah kopi ada di angka 42,6% serta memiliki kadar selulosa sebesar 27,4%. Berbagai komponen lain seperti gula, tanin, mineral, lemak, resin, dan asam volatil lemak juga terdapat pada daging buah kopi.

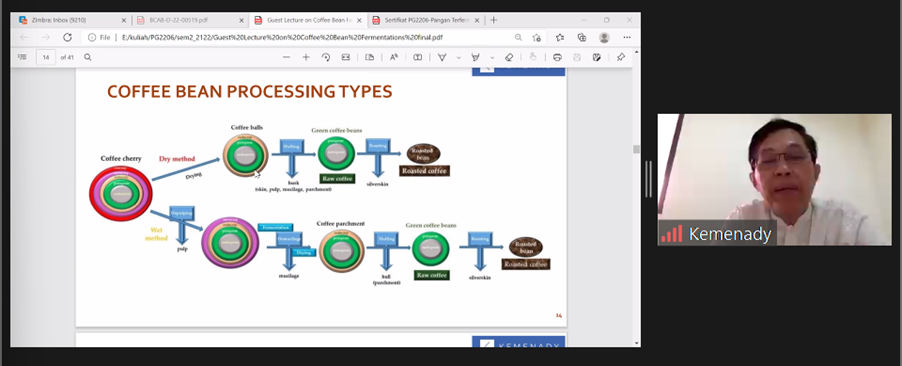

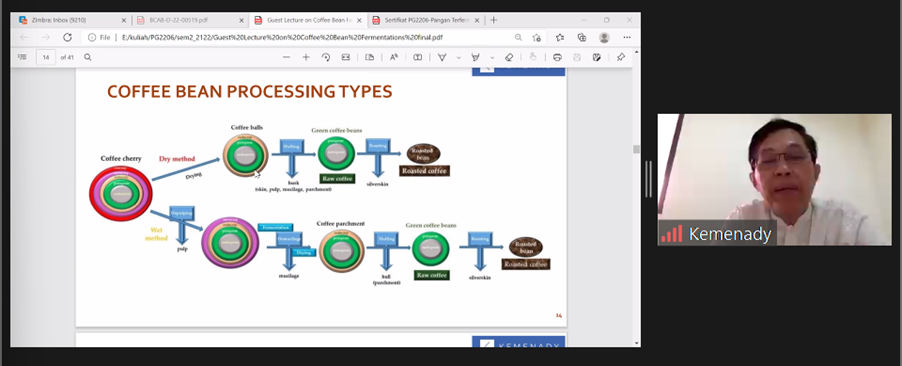

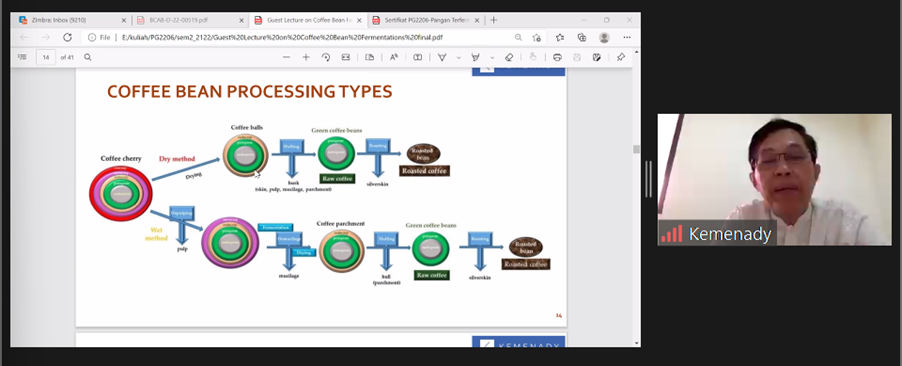

Secara garis besar, tahap pemrosesan kopi melalui berbagai tahap. Biji kopi yang masih berjenis cherry akan melalui proses depulping, fermentation, demucilage, dan drying sebelum menjadi green beans. Setelah biji kopi telah menjadi green beans, biji kopi akan dipanggang hingga menjadi roasted beans. “Secara spesifik, pemrosesan kopi dibedakan menjadi dua metode yaitu dengan dry method dan wet method,” jelas Eddy. Setiap proses yang dilalui oleh biji kopi ini akan merubah lapisan yang ada pada biji kopi.

Eddy menjelaskan, pada proses fermentasi kopi, jenis bakteri yang dilibatkan adalah bakteri Saccharomyces cerevisiae dan lactic acid bacteria. Proses fermentasi ini dilangsungkan di coffee fermentation tank. “Fermentasi kopi alami melibatkan campuran berbagai jenis mikroba. Substrat fermentasi adalah lendir biji segar yang tersusun dari karbohidrat. Produk yang terbentuk dari proses ini akan bersifat asam dengan PH 4.1 hingga 4.3. Sumber N dari protein dan unsur mikro dan makro sering menjadi nutrisi pembatas yang menyebabkan terjadinya hambatan atau berhentinya proses fermentasi,” jelas Eddy.

Fermentasi pada kopi dilakukan pada alat yang menggunakan material SS 304 dengan temperatur yang sangat dikontrol. Untuk menghasilkan biji kopi dengan keasaman yang kompleks, proses fermentasi dilakukan pada suhu 4 – 8 derajat celcius. Sementara untuk menghasilkan biji kopi dengan kemanisan yang lebih tinggi, fermentasi dilakukan pada suhu 18 – 20 derajat celcius.

“Berbagai proses pada fermentasi kopi seperti penentuan suhu, durasi, penggunaan dan pemilihan jenis mikroba, kualitas air, dan kebersihan peralatan harus sangat diperhatikan agar dapat menghasilkan rasa dari biji kopi yang diinginkan,” papar Eddy. Berbagai kejadian yang harus dihindari saat melakukan fermentasi kopi adalah waktu fermentasi yang terlalu lama, proses pencucian yang buruk, kotornya tempat penjemuran biji kopi, dan juga mesin pengering yang terlalu panas.

Proses fermentasi kopi yang dilakukan dengan baik dan sesuai akan melahirkan berbagai hasil pada biji kopi seperti penurunan kandungan oksigen, peningkatan kadar karbondioksida, penurunan kadar air, penurunan PH, dan terbentuknya berbagai produk fermentasi seperti asam laktat, asam asetat, asam propionat, asam format, etanol, hidrogen peroksida, senyawa volatil sebagai zat pengawet makanan, hingga meningkatnya citarasa kopi.

Berbagai contoh produk hasil fermentasi dari kopi yang sukses di pasaran di antaranya adalah kopi Arabica Gunung Arca, Robusta Gunung Arca, Kleverig Blend, Emergency Blend, Arabica Blend Banana Koko, Arabika Anaerob Gunung Arca, Arabica Cianjur Carbonic Maceration, dan Frinsa Super Ateng.

Reporter : Yoel Enrico Meiliano (Teknik Pangan, 2020)

[:en]

BANDUNG, itb.ac.id–Coffee is one of the most popular drinks in Indonesia and even in the world. Besides having a taste that many people like, coffee is also known to have health benefits. Indonesia is one of the countries that produces various and high-quality varieties of coffee beans. Various types of processed coffee have been widely known in Indonesia.

In a guest lecture for the course PG2206 Fermented Food, Friday (1/4/2022), Food Engineering Department, Faculty of Industrial Technology ITB, explained one method in coffee processing which is fermentation that is carried by Ir. Eddy Kemenady., M.M., M.P. from Kemenady Coffee and Co-Working Space.

At the beginning of the material, Eddy explained the content of coffee beans. Coffee bean consists of two main parts, namely coffee mucilage and coffee fruit pulp. In addition, other parts found in coffee beans are parchment, silverskin, and bean.

In chemical composition, fruit mucilage in coffee is dominated by water up to 84.2%. The fruit mucus in coffee beans also consists of 8.9% protein and 4.1% sugar. Meanwhile, the water content in coffee fruit pulp is at 42.6% and cellulose content is 27.4%. Various other components such as sugar, tannin, minerals, fats, resins, and volatile fatty acids are also found in coffee fruit pulp.

Broadly speaking, the coffee processing stage goes through various stages. Coffee beans that are still in the cherry phase will go through a process of depulping, fermentation, demucilage, and drying before becoming green beans. After the coffee beans have become green beans, the coffee beans will be roasted until they become roasted beans. “Specifically, coffee processing is divided into two methods, namely the dry method and the wet method,” explained Eddy. Each process that the coffee beans go through will change the coating on the coffee beans.

Eddy explained that in the coffee fermentation process, the types of bacteria involved were Saccharomyces cerevisiae and lactic acid bacteria. This fermentation process is carried out in a coffee fermentation tank. “Natural coffee fermentation involves a mixture of different types of microbes. Fermentation substrate is fresh bean mucilage which contain carbohydrates. The product formed from this process will be acidic with a pH of 4.1 to 4.3. Sources of N from protein and micro and macro elements often become limiting nutrients that cause inhibition or cessation of the fermentation process,” explained Eddy.

Fermentation on coffee is carried out in a tool that is made of SS 304 material with a carefully controlled temperature. To produce coffee beans with complex acidity, the fermentation process is carried out at a temperature of 4 – 8 degrees Celsius. Meanwhile, to produce coffee beans with higher sweetness, fermentation is carried out at a temperature of 18 – 20 degrees Celsius.

“Various processes in coffee fermentation such as determining temperature, duration, use and selection of microbial types, water quality, and cleanliness of equipment must be considered in order to produce the desired taste of coffee beans,” said Eddy. Various cases that must be avoided when fermenting coffee are fermentation times that are too long, a poor washing process, dirty coffee bean drying places, and also drying machines that are too hot.

The coffee fermentation process that is carried out properly and appropriately will produce various results in coffee beans such as decreased oxygen content, increased carbon dioxide levels, decreased water content, decreased pH, and the formation of various fermentation products such as lactic acid, acetic acid, propionic acid, formic acid, ethanol, hydrogen peroxide, volatile compounds as food preservatives, to increase the taste of coffee.

Various examples of fermented coffee products that are successful in the market include Gunung Arca Arabica coffee, Gunung Arca Robusta, Kleverig Blend, Emergency Blend, Banana Koko Arabica Blend, Gunung Arca Anaerobic Arabica, Cianjur Carbonic Maceration Arabica, and Frinsa Super Ateng.

Reporter : Yoel Enrico Meiliano (Food Engineering, 2020)[:]

[:en]

[:en]