Marhaban Ya Ramadhan 1443 H

BANDUNG, itb.ac.id–Coffee is one of the most popular drinks in Indonesia and even in the world. Besides having a taste that many people like, coffee is also known to have health benefits. Indonesia is one of the countries that produces various and high-quality varieties of coffee beans. Various types of processed coffee have been widely known in Indonesia.

In a guest lecture for the course PG2206 Fermented Food, Friday (1/4/2022), Food Engineering Department, Faculty of Industrial Technology ITB, explained one method in coffee processing which is fermentation that is carried by Ir. Eddy Kemenady., M.M., M.P. from Kemenady Coffee and Co-Working Space.

At the beginning of the material, Eddy explained the content of coffee beans. Coffee bean consists of two main parts, namely coffee mucilage and coffee fruit pulp. In addition, other parts found in coffee beans are parchment, silverskin, and bean.

In chemical composition, fruit mucilage in coffee is dominated by water up to 84.2%. The fruit mucus in coffee beans also consists of 8.9% protein and 4.1% sugar. Meanwhile, the water content in coffee fruit pulp is at 42.6% and cellulose content is 27.4%. Various other components such as sugar, tannin, minerals, fats, resins, and volatile fatty acids are also found in coffee fruit pulp.

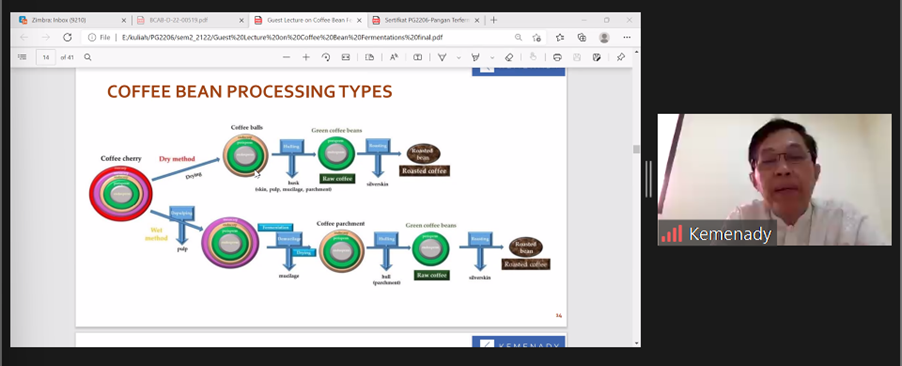

Broadly speaking, the coffee processing stage goes through various stages. Coffee beans that are still in the cherry phase will go through a process of depulping, fermentation, demucilage, and drying before becoming green beans. After the coffee beans have become green beans, the coffee beans will be roasted until they become roasted beans. “Specifically, coffee processing is divided into two methods, namely the dry method and the wet method,” explained Eddy. Each process that the coffee beans go through will change the coating on the coffee beans.

Eddy explained that in the coffee fermentation process, the types of bacteria involved were Saccharomyces cerevisiae and lactic acid bacteria. This fermentation process is carried out in a coffee fermentation tank. “Natural coffee fermentation involves a mixture of different types of microbes. Fermentation substrate is fresh bean mucilage which contain carbohydrates. The product formed from this process will be acidic with a pH of 4.1 to 4.3. Sources of N from protein and micro and macro elements often become limiting nutrients that cause inhibition or cessation of the fermentation process,” explained Eddy.

Fermentation on coffee is carried out in a tool that is made of SS 304 material with a carefully controlled temperature. To produce coffee beans with complex acidity, the fermentation process is carried out at a temperature of 4 – 8 degrees Celsius. Meanwhile, to produce coffee beans with higher sweetness, fermentation is carried out at a temperature of 18 – 20 degrees Celsius.

“Various processes in coffee fermentation such as determining temperature, duration, use and selection of microbial types, water quality, and cleanliness of equipment must be considered in order to produce the desired taste of coffee beans,” said Eddy. Various cases that must be avoided when fermenting coffee are fermentation times that are too long, a poor washing process, dirty coffee bean drying places, and also drying machines that are too hot.

The coffee fermentation process that is carried out properly and appropriately will produce various results in coffee beans such as decreased oxygen content, increased carbon dioxide levels, decreased water content, decreased pH, and the formation of various fermentation products such as lactic acid, acetic acid, propionic acid, formic acid, ethanol, hydrogen peroxide, volatile compounds as food preservatives, to increase the taste of coffee.

Various examples of fermented coffee products that are successful in the market include Gunung Arca Arabica coffee, Gunung Arca Robusta, Kleverig Blend, Emergency Blend, Banana Koko Arabica Blend, Gunung Arca Anaerobic Arabica, Cianjur Carbonic Maceration Arabica, and Frinsa Super Ateng.

Reporter : Yoel Enrico Meiliano (Food Engineering, 2020)

BANDUNG, itb.ac.id – Himpunan Mahasiswa Teknik Pangan Institut Teknologi Bandung (HMPG ITB) held a webinar on food engineering on Saturday (5/2/2022). As one of a series of events from the Food Engineering Festival (FEF ITB), this activity has the title of “Foreseeing The Future of Food Engineering” and was brought by Dr. Ir. Dianika Lestari, S.T., M.T.

This Food Engineering ITB lecturer started her presentation about the role of food engineers, namely in designing and developing technology and systems for the production, distribution, storage of agricultural products and food ingredients on a commercial scale. “Food engineers also play a role in finding solutions to problems in food processing on an industrial scale,” explained Dr. Dianika.

Of course, to perform these various tasks, food engineers are not alone. There are various aspects that food engineers must understand. Starting from food commodities where food engineers will work closely with agricultural engineers and post-harvest engineering engineers.

Then food engineers must also understand food additives and food ingredients to produce safe and good food products, which can then be distributed to the consumers in the market.

Currently, of course, there are still some problems in the food sector in Indonesia. First, the use of Indonesian food raw materials for food components or ingredients is still limited. In addition, Indonesian process engineers are still limited in designing food production process technology to process local Indonesian food raw materials in a sustainable manner.

Therefore, food engineers from the Food Engineering study program have various tasks and roles for the future of Indonesian food. First, Indonesian food engineers must be able to create new technologies to exploit the potential of Indonesia’s food resources. This is certainly something that must be realized immediately because Indonesia has a lot of potential food resources that are rich in nutritional content that can be commercialized and also developed to help the economy, prosper the community, and advance the Indonesian state.

Second, the quality of the food produced must be very carefully considered and also maintained very well because food ingredients are sensitive materials and are in direct contact with humans completely. “Food products must be maintained for their continuity, quality, and capacity so that they can be accepted by the industry,” said Dianika.

Healthy and delicious food should be the goal of assembling future food processing technology. The production of healthy food on a commercial industrial scale will make it more affordable for the wider community.

On the other hand, engineers from Food Engineering and ITB in general have also contributed to producing various future food processing technologies for Indonesia. The results created are Closed Circulated Batch Reactor and Closed Circulated Semi-Continuous Reactor. Both of these reactors have various advantages. Starting from more efficient water consumption, better hygiene control, and a larger load of materials to be processed.

The second problem that food engineers must also solve is food waste, which is now a big problem all over the world. On a national scale, the estimated total food loss or food waste in Indonesia is 18 to 31 million tons per year. Of course, this is an urgent condition for improvement. The solution currently being developed by food engineers is technology for processing dried fruit and further processing food waste into materials that can be used for other things.

“Not only that, food engineers must also be able to improve the existing technology to become more efficient and resource-efficient technology,” explained Dianika.

In addition, Dianika continued, food engineers must also adapt and be able to keep up with the times, especially in Industry 4.0 which is rife with industrial automation, especially in the food processing, food packaging, and food servicing sectors, which are now mostly run by machines and technology.

Reporter : Yoel Enrico Meiliano (Food Engineering, 2020)

BANDUNG, itb.ac.id—Prof. Lienda Aliwarga Handojo as a professor of Food Processing Technology Science, Faculty of Industrial Technology, ITB, explained various researches and studies that have been carried out. The presentation was held on Saturday (11/12/2021) along with the scientific oration she delivered.

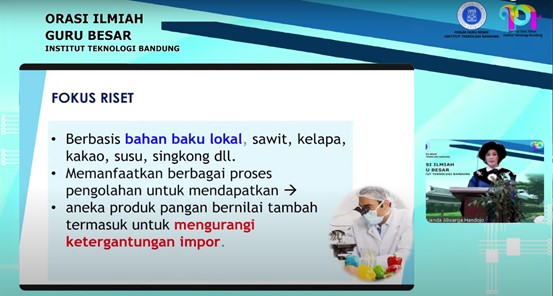

Prof. Lienda’s research focuses on research based on local raw materials such as palm oil, coconut, cocoa, cassava, etc. The research process is carried out by utilizing various processing processes to obtain various value-added food products including reducing dependence on imports.

The first research conducted was a calcium soap animal feed supplement. The purpose of this study is to reduce imports of Indonesian milk by increasing the productivity and quality of local cow’s milk. Calcium soap or often known as calcium fat, is obtained from the reaction of Palm Fatty Acid Distillate (PFAD) with lime. PFAD is a by-product of the Crude Palm Oil refining process which is very abundant in Indonesia.

This supplement can significantly increase the productivity of dairy cows’ milk, including its quality. The test results show that the quality of the calcium soap produced is slightly superior to similar products on the foreign market. This research has been stated in the form of 3 patents.

Next is the study of fermented cassava flour (fercaf). This research succeeded in developing fercaf which functions as food diversification or as a substitute for imported wheat flour. The results of this research have obtained a patent and were applied by PT Cassava Industri Estat Tujuh Sembilan in 2017 who produces fercaf on a commercial scale.

Several other studies have also been successfully carried out. Processing whey for nutritious drinks, for example. Whey which is a cheese factory waste still contains about 6 grams of protein/liter so it can be processed to produce nutritious drinks. “Coconut water processing for ready-to-drink drinks uses membrane technology. As well as processing stevia leaves as a source of low-calorie natural sugar,” he said.

In addition to the research previously mentioned, adaptation of new technologies (novel processes) for food processing was also carried out. Pulse Electric Field for preservation of avocado paste and ginger paste. Because as is known, avocado is a fruit that is not heat-resistant so that thermal preservation cannot be done. There is also an edible coating that can be used to extend the shelf life of the fruit.

Prof. Lienda conveyed several messages about the potential of the food industry in the future. “There will still be a variety of new technologies that require refinement through various studies. The success of research in universities cannot go alone. Synergy from all stakeholders is needed in preparation for Indonesia to compete and face global challenges in the food industry in the future,” said Prof. Lienda.

Reporter : Anastasia Meliana (Pharmaceutical Science and Technology, 2019)