BANDUNG, itb.ac.id–Food Engineering Department, Faculty of Industrial Technology ITB and the Department of Professional Development of Himpunan Mahasiswa Teknik Pangan ITB (HMPG ITB) are collaborating to hold a webinar related to Alkalization of Chocolate which is part of the series of events “Webinars for Alkalization of the Nibs Process, Massa, and Cocoa Cake” Saturday (6/11/2021). This webinar presents the Director of Espe Food and the author of the book “Kakao dan Teknologi Produksi Coklat”, Drs. Susanto Purwo as the presenter.

At the beginning of this session, Drs. Susanto explained about alkalization in general. “Alkalization process is the process of adding alkali to nib, mass, and cocoa cake which aims to raise the pH and create color and improve product solubility,” said Drs. Susanto. Various types of alkali that can be used are K2CO3, MgCO3, Na2CO3, NH4CO3, and many more. Through the process of alkalization, the solubility, color, and taste of cocoa will change.

One of the purposes of this alkalization is to increase the solubility of cocoa. “Until now, cocoa powder itself cannot be made until it has 100% solubility, therefore we can only improve the solubility of cocoa through this alkalization process,” said Drs. Susanto.

Furthermore, Drs. Susanto explained about the role of the alkalization process in the formation of cocoa flavor and aroma. According to research by Li, the acid which is 60% of the fraction in cocoa is volatile. Through the alkalization process, the evaporated acid is only 30%. In the alkalization process, glycosylated flavanols are formed which play a role in reducing the bitter taste. In addition, glycosylation reactions can also reduce astringency.

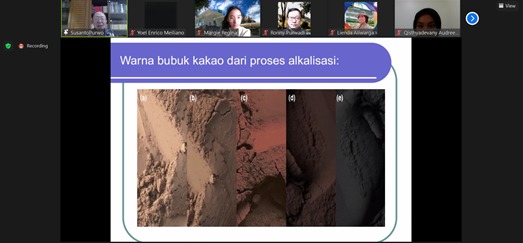

In this alkalization process, of course, chemical changes also occur. First, there is a change in pH to be higher. Then there are also changes in temperature, vapor pressure, and oxygen levels. In addition, the longer the alkalization process, the better the color of the cocoa produced. During the alkalization process, several reactions occur. Starting from the neutralization reaction of acids, hydrolysis reactions of glycosides, hydrolysis reactions of esters which play a role in facilitating interactions with compounds that form cocoa flavors and aromas, Maillard reactions to create new flavors and aromas from cocoa, and various other reactions.

Drs. Susanto also explained various techniques of the alkalization process. Starting from the alkalization process on the cocoa nib, the alkalization process on the cocoa mass, and the alkalization process on cocoa powder. “This alkalization process is carried out on different cocoa components because cocoa machine companies are trying to create new things in the cocoa manufacturing process,” said Drs. Susanto. Therefore, a lot of patent research is being carried out by machine manufacturers and large cocoa factories in the world.

Reporter : Yoel Enrico Meiliano, Food Engineering 2020